Steel Drag Chain - Durable Cable Management Solutions for Industry

The Functionality and Importance of Steel Drag Chains

In various industrial settings, the efficient management and protection of cables and hoses are crucial for operational productivity and safety. Among the various solutions available, steel drag chains stand out as a reliable and durable option. These chains play an essential role in safeguarding and organizing cables as they move with machinery, ensuring smooth operation and minimizing wear and tear.

Steel drag chains, also known as cable carriers or energy chains, are designed to guide and protect flexible cables and hoses that are frequently subjected to bending and movement during operation. Their robust construction allows them to withstand severe environments, including high temperatures, harsh chemicals, and mechanical stress. This makes them particularly valuable in sectors like automation, robotics, and material handling, where equipment is constantly in motion.

One of the key advantages of steel drag chains is their capability to maintain cable integrity. Traditional cable management methods, such as bundling wires together, often lead to issues like tangling or excessive friction. In contrast, drag chains provide an organized pathway that keeps cables separated and free from abrasion. This not only prolongs the lifecycle of the cables but also reduces downtime caused by cable failures.

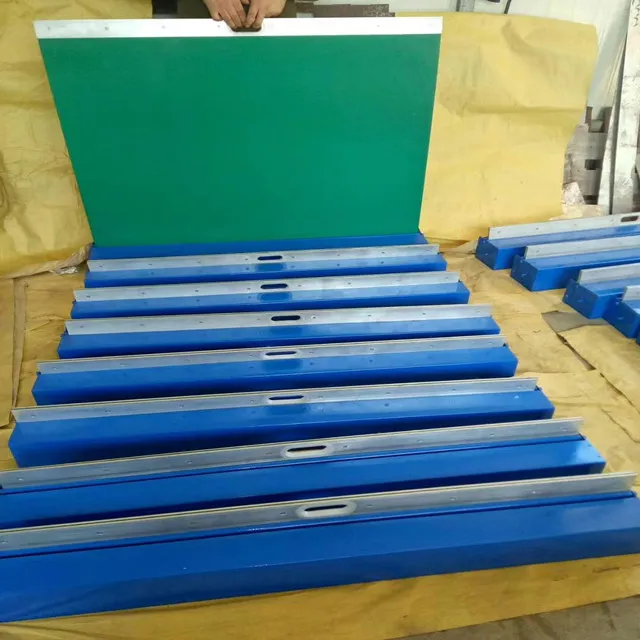

steel drag chain

In addition to their protective features, steel drag chains enhance the overall efficiency of machinery

. By allowing cables to move in a controlled manner, they help maintain the smooth operation of equipment, which is crucial for ensuring productivity in fast-paced industrial environments. Furthermore, the predictable movement of cables reduces the risk of entanglement, which can lead to unexpected machinery halts and potential safety hazards.The installation of a steel drag chain system can be customized to meet the specific requirements of a given application. This includes considerations for the type and quantity of cables, the environmental conditions they will face, and the motion dynamics of the equipment involved. Many manufacturers offer a range of sizes and configurations, allowing businesses to optimize their drag chain systems for maximum efficiency and safety.

Economically, investing in steel drag chains can lead to significant savings in the long run. By enhancing the durability of cables and minimizing maintenance needs, these systems help reduce operational costs associated with repairs and replacements. Additionally, the improved safety and reliability of machinery can contribute to greater overall productivity, aligning with modern industry demands for efficiency and high performance.

In conclusion, steel drag chains are a vital component in industrial environments where cable management is necessary for operational success. Their ability to protect and organize cables, reduce wear and tear, and enhance machine efficiency makes them an indispensable asset in the quest for streamlined operations and optimal productivity. As industries continue to evolve, the significance of effective cable management solutions like steel drag chains will only grow, underpinning their role in modern manufacturing and automation processes.