swarf conveyors

Understanding Swarf Conveyors Essential Equipment for Modern Manufacturing

In the realm of modern manufacturing, efficiency and productivity are paramount. Among the various tools and technologies that enhance these aspects, swarf conveyors stand out as essential equipment. Swarf, which refers to the debris produced during machining processes such as cutting, milling, and grinding, poses significant challenges in factory settings. Swarf conveyors are designed to handle this waste efficiently, promoting a cleaner workspace and contributing to operational effectiveness.

What are Swarf Conveyors?

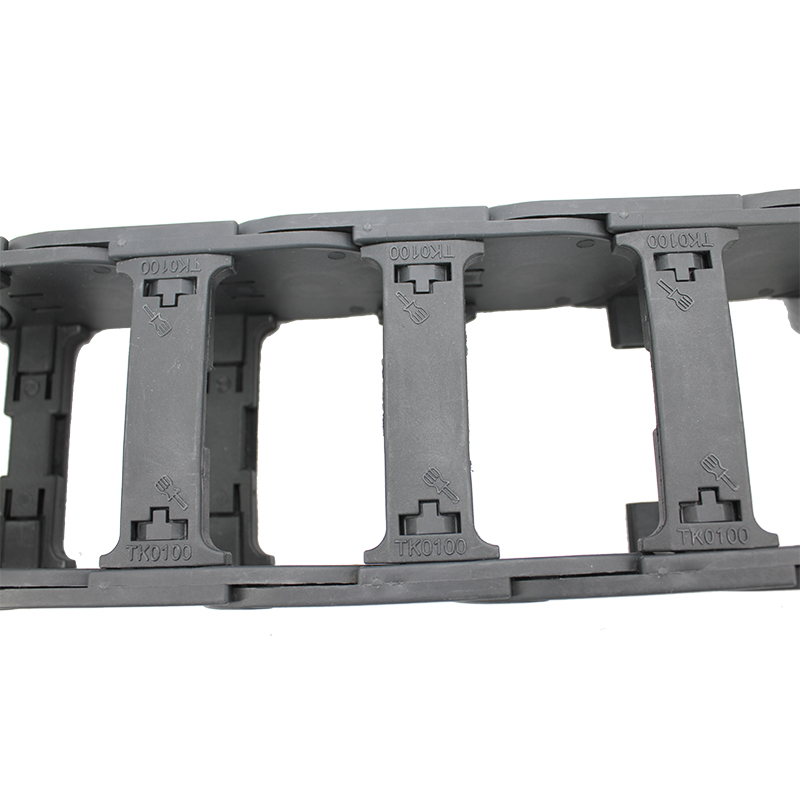

Swarf conveyors are mechanical systems specifically engineered to transport and manage swarf away from machining processes. These systems come in various forms, including screw, belt, magnetic, and scraper conveyors. Each type is designed to suit different types of swarf and machining processes, ensuring that manufacturers can choose the right equipment for their specific needs.

Importance in Manufacturing

The importance of swarf conveyors cannot be overstated. During machining operations, swarf can accumulate quickly, leading to several issues

1. Safety Hazards Piles of metal shavings or chips can create tripping hazards and fire risks, especially when they’re mixed with lubricants or coolants. 2. Equipment Efficiency Excessive swarf can hinder machine operation, leading to increased wear and tear, reduced machining precision, and potential machine failures.

3. Environmental Considerations Improper disposal of metal waste can have negative environmental effects. Swarf conveyors help in collecting and transporting the debris to proper recycling or disposal systems.

4. Cost Implications By effectively managing waste, companies can reduce the costs associated with downtime, machine repairs, and waste disposal.

Types of Swarf Conveyors

1. Screw Conveyors This type uses a helical screw blade to move swarf along a trough. They are versatile and particularly effective for handling plastic and metal swarf in a continuous motion.

swarf conveyors

2. Belt Conveyors Utilized in many industries, belt conveyors transport swarf across varying distances. They are suitable for larger chips and shavings and can be equipped with side skirts to prevent spillage.

3. Magnetic Conveyors Best suited for ferrous materials, magnetic conveyors utilize magnets to hold and move metal swarf. This type is particularly useful for fine chips and is often employed in precision machining processes.

4. Scraper Conveyors For heavy and bulky swarf, scraper conveyors provide an effective solution. They use a series of scrapers that slide along a channel to move larger swarf materials.

Advantages of Using Swarf Conveyors

1. Improved Workspace Safety By continuously removing waste, swarf conveyors help maintain a safer working environment, reducing the likelihood of accidents.

2. Enhanced Productivity With a clean workspace, machines can operate at peak efficiency, minimizing downtime and maximizing production output.

3. Reduced Environmental Impact Efficient swarf management contributes to sustainability efforts by facilitating recycling and reducing waste.

4. Customization Many swarf conveyors can be tailored to suit specific production needs, enhancing their effectiveness in diverse manufacturing environments.

Conclusion

Swarf conveyors play a crucial role in modern manufacturing processes by providing effective solutions for swarf management. As industries strive for greater efficiency and sustainability, the importance of such specialized equipment becomes increasingly evident. Investing in the right type of swarf conveyor not only enhances safety and productivity but also contributes to a cleaner and more environmentally responsible manufacturing environment. In an age where efficiency is key, swarf conveyors prove to be indispensable tools in the manufacturing arsenal. As manufacturers continue to innovate and improve their processes, the role of swarf conveyors will undoubtedly remain significant.