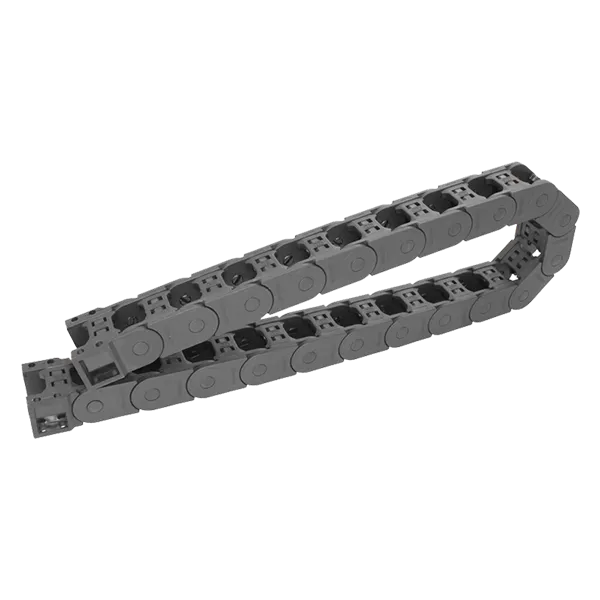

synchro belt

Understanding the Importance of Synchro Belts in Modern Machinery

In the realm of mechanical engineering, the synchro belt is an unsung hero that plays a crucial role in various applications, including automotive, industrial machinery, and power transmission systems. Often referred to as synchronous belts or timing belts, these components are essential for ensuring precise movement and synchronized rotation in machines.

One of the most significant features of synchro belts is their design, which facilitates a smooth and reliable transfer of power. Composed of a reinforced rubber body with teeth that mesh with corresponding grooves on pulleys, synchro belts prevent slippage and allow for accurate timing between driving and driven components. This is particularly important in applications where the timing of movements must be coordinated, such as in engine timing systems in vehicles, where the synchronization of the camshaft and crankshaft is vital for optimal performance.

The advantages of synchro belts over traditional V-belts are numerous. For instance, synchro belts experience minimal stretch over time, ensuring that the distance between the pulleys remains consistent. This stability leads to a longer lifespan for the belt and the components it connects, reducing maintenance costs and downtime. Additionally, synchro belts operate with less noise and vibration compared to other belt systems, contributing to a quieter work environment.

Maintenance of synchro belts is also straightforward. Regular inspections for wear and tear, along with checking proper tension, will help in prolonging their life. Unlike chains or gears, synchro belts do not require lubrication, which simplifies maintenance tasks. However, if a belt does show signs of damage—such as cracks, fraying, or missing teeth—prompt replacement is necessary to prevent catastrophic failures in machinery.

synchro belt

Another critical aspect of synchro belts is their versatility in design. They are available in various widths, lengths, and tooth configurations, allowing engineers to select the optimal option for their specific application. Whether it’s for small robots or large conveyor systems, synchro belts can be customized to meet the exact requirements of speed, torque, and load capacity.

In addition to their application in mechanical systems, synchro belts have found their way into consumer products, such as printers, exercise equipment, and even kitchen appliances. The precision and reliability they offer make them an ideal choice for devices where accurate movement is essential.

As industries continue to evolve with advancements in technology, the demand for efficient and reliable power transmission solutions like synchro belts will only increase. Innovations in materials and manufacturing techniques are leading to even stronger and more durable belts. Furthermore, as the trend toward automation and robotics grows, the role of synchro belts in driving these systems becomes increasingly important.

In conclusion, synchro belts are critical components that ensure the efficient operation of various mechanical systems. Their unique design, low maintenance requirements, long lifespan, and versatility make them indispensable in modern machinery. As technology progresses, the synchro belt will continue to be a vital element in the pursuit of greater efficiency and precision across numerous industries.