synchronous belt drive

Understanding Synchronous Belt Drive Mechanism and Applications

Synchronous belt drive systems have become integral in various mechanical applications, providing efficient power transmission mechanisms across numerous industries. Unlike traditional belt drives, which rely on friction to transmit power, synchronous belt drives utilize a toothed belt and pulleys, ensuring that the belt and pulleys engage in synchrony. This unique design minimizes slippage, which leads to higher efficiency, greater accuracy, and reduced maintenance needs.

Mechanism of Synchronous Belt Drive

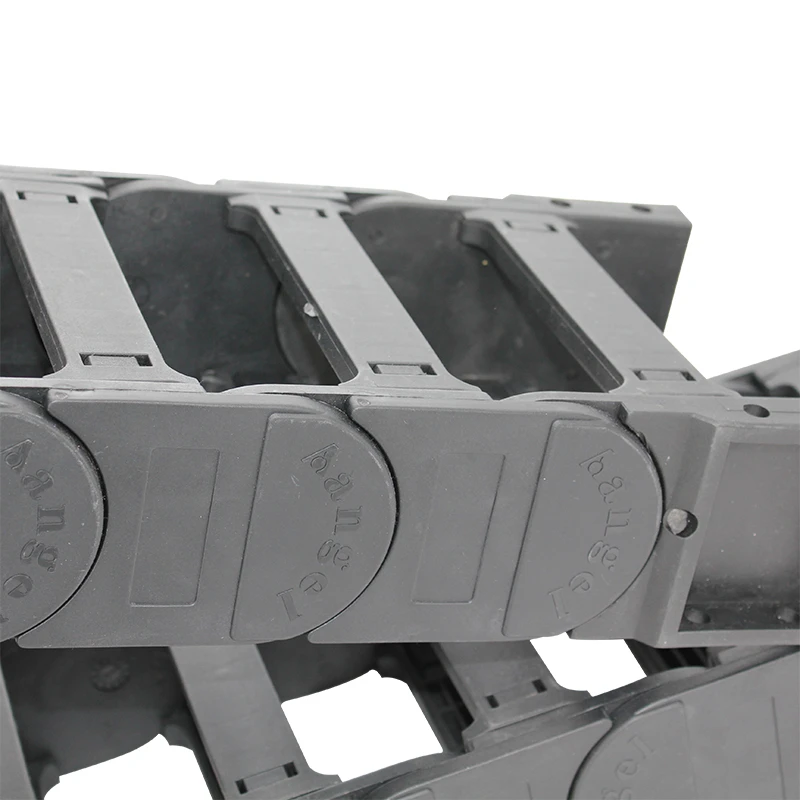

The primary components of a synchronous belt drive are the toothed belt, pulleys (or sprockets), and the drive mechanism. The toothed belt, often made from elastomeric materials reinforced with fibers, features evenly spaced teeth on its inner side. These teeth mesh with corresponding grooves on the pulleys, creating a positive engagement that prevents slippage.

This positive engagement enables the drive system to maintain precise timing between the driving and driven components. As the driving pulley rotates, it pulls the toothed belt, which in turn moves the driven pulley in perfect synchronization. This mechanism is particularly beneficial in applications requiring precise timing and positioning, such as in robotics, conveyor systems, and machining operations.

Advantages of Synchronous Belt Drive

One key advantage of synchronous belt drives is their efficiency

. Because there is no slippage, these systems can achieve power transmission efficiencies of up to 98%. This high efficiency translates into lower energy consumption, which is increasingly important in today’s environmentally-conscious industrial landscape.Additionally, synchronous belts tend to require less maintenance than traditional belt systems. Since they do not rely on tension adjustments and have no risk of slippage, operators can save time and resources usually spent on maintenance and adjustments. Furthermore, the absence of lubrication requirements minimizes the mess and potential hazards associated with lubricated systems.

synchronous belt drive

Another significant advantage is the ability to operate at high speeds. Synchronous belt drives can efficiently function at higher rotational speeds compared to their friction-driven counterparts. This characteristic is pivotal in industries where rapid movement leads to increased productivity and efficiency, such as in automated assembly lines.

Applications of Synchronous Belt Drives

The applications of synchronous belt drives span various industries, including automotive, manufacturing, aerospace, and robotics. In the automotive industry, these systems are commonly found in timing belts that synchronize the rotation of the crankshaft and camshaft, ensuring smooth engine operation. The precision of these drives is critical for engine performance and reliability.

In manufacturing, synchronous belt drives power conveyor systems that transport materials and products through different stages of production. The ability to maintain accurate positioning and timing is crucial in assembly lines where specific processes depend on the synchronized movement of components.

Moreover, in the field of robotics, synchronous belt drives are essential for precise movement control. They allow robots to perform tasks with a high degree of accuracy, essential in industries such as electronics, pharmaceuticals, and food processing where precision and consistency are paramount.

Additionally, in the aerospace industry, these drives are utilized in various applications, including control systems in aircraft and drones, where reliable and precise motion is critical for safety and performance.

Conclusion

In summary, synchronous belt drives are a highly efficient and reliable method for power transmission across a wide array of applications. Their unique design and the absence of slippage contribute to their high efficiency, low maintenance needs, and suitability for high-speed operations. As industries continue to advance and demand higher efficiency and precision, the synchronous belt drive system will undoubtedly play an increasingly significant role in the design and optimization of mechanical systems. Whether in automotive engines, manufacturing processes, or robotics, the relevance of this technology in modern engineering cannot be overstated. Embracing innovations in synchronous belt drive technology will further enhance its application and broaden its impact across various sectors.