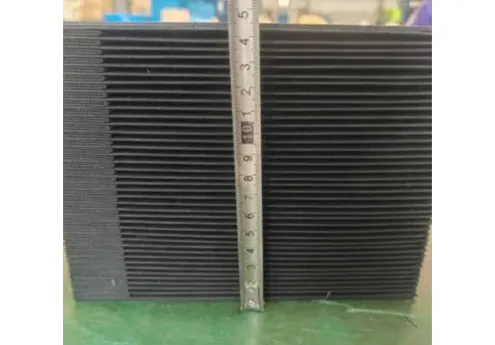

synchronous belt pulley

The debate between synchronous belts and timing belts is a topic of significant interest and relevance to anyone involved with mechanical systems or automotive design. Both types of belts play crucial roles in machinery, but their applications, construction, and performance can differ considerably. Understanding these differences not only demonstrates technical expertise but also enhances trust in an author's authority on the subject.

The expertise required in selecting an appropriate belt also includes understanding potential failure modes. Synchronous belts can fail due to over-tensioning, pulley misalignment, or extreme temperatures. On the other hand, timing belts may wear out due to the constant engine heat and stress, leading to cracks or splits over time. Regular inspection and maintenance routines are pivotal in preempting such failures, emphasizing the importance of having a knowledgeable perspective on their correct application and longevity management. From an authority standpoint, manufacturers often provide detailed guides and specifications about their belts' performance. Engaging with these resources, and possibly even consulting with the manufacturer in complex situations, can solidify an engineer’s expertise in this field. By doing so, one ensures that the applied solution in machinery is not just theoretically sound but also practically verified against real-world conditions. Finally, trustworthiness is enhanced by referencing experiences and testimonials from mechanical engineers and automotive experts who have first-hand experience with both synchronous and timing belts. These insights are invaluable, providing practical notes on installation challenges, operational contexts, and issues encountered over product lifecycles. Authentic, experience-driven narratives help validate the choice of a specific belt type for a given machinery project, bolstering confidence in the decision-making process. In conclusion, although synchronous belts and timing belts share similarities, their differences are crucial depending on the context of their application. Making informed choices backed by expert insights and authoritative knowledge not only enhances the functionality of mechanical systems but also builds trust in the reliability and efficiency these components promise. For anyone involved in design and maintenance, these insights serve not just as guidelines but as a basis for achieving optimal performance and extending the lifespan of critical machinery.

The expertise required in selecting an appropriate belt also includes understanding potential failure modes. Synchronous belts can fail due to over-tensioning, pulley misalignment, or extreme temperatures. On the other hand, timing belts may wear out due to the constant engine heat and stress, leading to cracks or splits over time. Regular inspection and maintenance routines are pivotal in preempting such failures, emphasizing the importance of having a knowledgeable perspective on their correct application and longevity management. From an authority standpoint, manufacturers often provide detailed guides and specifications about their belts' performance. Engaging with these resources, and possibly even consulting with the manufacturer in complex situations, can solidify an engineer’s expertise in this field. By doing so, one ensures that the applied solution in machinery is not just theoretically sound but also practically verified against real-world conditions. Finally, trustworthiness is enhanced by referencing experiences and testimonials from mechanical engineers and automotive experts who have first-hand experience with both synchronous and timing belts. These insights are invaluable, providing practical notes on installation challenges, operational contexts, and issues encountered over product lifecycles. Authentic, experience-driven narratives help validate the choice of a specific belt type for a given machinery project, bolstering confidence in the decision-making process. In conclusion, although synchronous belts and timing belts share similarities, their differences are crucial depending on the context of their application. Making informed choices backed by expert insights and authoritative knowledge not only enhances the functionality of mechanical systems but also builds trust in the reliability and efficiency these components promise. For anyone involved in design and maintenance, these insights serve not just as guidelines but as a basis for achieving optimal performance and extending the lifespan of critical machinery.