Comparing Synchronous Belts and Timing Belts for Optimal Performance and Efficiency

Synchronous Belt vs. Timing Belt Understanding the Differences and Applications

When it comes to mechanical systems where precision and synchronization are key, two commonly used components often come to mind synchronous belts and timing belts. While the terms are sometimes used interchangeably, there are significant differences between the two, and understanding these distinctions can help in selecting the right component for various applications.

Definition and Structure

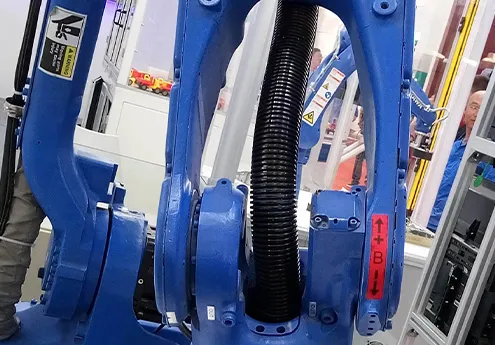

A synchronous belt is a type of drive belt designed with evenly spaced teeth that engage with sprockets or pulleys, ensuring that the movement is synchronized between two or more rotating shafts

. This belt is essential for applications where precise timing is critical, such as in robotics, conveyor systems, and automotive engines.On the other hand, a timing belt also features teeth, but it is primarily used in internal combustion engines to synchronize the movements of the crankshaft and camshaft. Timing belts are typically made from rubber with reinforcement materials, which provide durability and flexibility. Their design allows them to transmit power while preventing slippage, ensuring that the engine's timing remains accurate.

Key Differences

One of the primary differences between synchronous and timing belts lies in their applications. Synchronous belts are commonly employed in industries where continuous motion is required, such as in automated manufacturing equipment and linear motion systems. These belts can drive multiple rollers or wheels, making them versatile for various machinery setups.

synchronous belt vs timing belt

Conversely, timing belts are predominantly found in automotive applications. They play a crucial role in the engine's operation, connecting the crankshaft to the camshaft. This connection is vital for the engine's timing and efficiency, and any failure in the timing belt can lead to severe engine damage.

Another difference is in their maintenance and longevity. Synchronous belts can often last longer and require less maintenance due to their robust design. Timing belts, however, typically require regular inspection and replacement to prevent breakdowns, as they are subject to wear and tear, particularly in high-temperature environments.

Materials and Manufacturing

Both belts can be made from similar materials, including rubber and polyurethane, but the specific formulations and manufacturing processes may differ based on their intended use. Synchronous belts are often made with high-strength materials to withstand continuous operation, while timing belts must also incorporate properties that handle high levels of stress and heat, particularly in automotive applications.

Conclusion

In conclusion, both synchronous belts and timing belts play essential roles in mechanical systems, but their applications, maintenance requirements, and structural designs set them apart. When choosing between the two, it is vital to consider the specific needs of your application. For manufacturing and general movement applications, a synchronous belt may be the ideal choice. For automotive purposes, a timing belt is necessary to ensure the engine runs smoothly and efficiently. Understanding these differences can lead to better decisions and enhanced performance in any mechanical system.