Understanding the Mechanics of Synchronous Belt Wheels for Efficient Power Transmission

Understanding Synchronous Belt Wheels Key Components in Mechanical Systems

Synchronous belt wheels, also known as timing pulleys or synchronous pulleys, play a crucial role in various mechanical systems by ensuring precise timing and synchronization between rotating components. Unlike traditional V-belts that rely on friction to transmit power, synchronous belts engage with the teeth on the belt and the grooves on the pulleys, which allows for more reliable and efficient motion transfer. This article explores the construction, functionality, applications, and advantages of synchronous belt wheels.

Construction and Design

The construction of synchronous belt wheels typically involves a durable material, such as aluminum or hard plastic, designed to withstand significant wear and tear. The key feature of these wheels is the toothed design, which corresponds perfectly with the tooth profile of the synchronous belt. The teeth not only help in locking the belt in place but also reduce the risk of slippage that can lead to inaccuracies in movement. Moreover, synchronous belt wheels come in various sizes and configurations depending on the application, allowing for flexibility in design.

Functionality

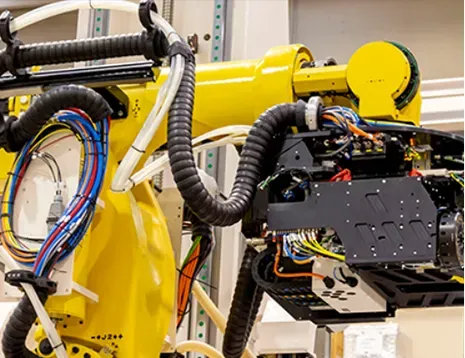

The primary function of synchronous belt wheels is to convert rotary motion into linear motion, or vice versa, while maintaining a specific timing relationship between the components they connect. This is particularly important in applications where precision is paramount, such as in automotive timing systems, CNC machinery, and robotics. The synchronous motion achieved by these wheels ensures that the connected parts operate in harmony, preventing issues that could arise from misalignment or delays in movement.

synchronous belt wheel

Applications

Synchronous belt wheels are widely used across various industries, including automotive, manufacturing, and aerospace. In automotive applications, they are integral to timing belts that synchronize engine components, ensuring the valves and pistons operate in unison. In manufacturing, synchronous belts drive conveyor systems, cutting machines, and other equipment requiring high levels of precision and reliability. Additionally, these wheels are prevalent in robotics, where they allow for controlled and accurate movement of robotic arms and other automated systems.

Advantages

The advantages of using synchronous belt wheels are numerous. Firstly, their ability to eliminate slippage enhances the precision of the systems they support. Secondly, since they are designed to operate without the friction that characterizes traditional V-belts, they result in lower wear and maintenance costs. Moreover, synchronous belts can operate at higher speeds, contributing to increased efficiency in various applications. Lastly, because they can be designed in various shapes and sizes, manufacturers can tailor them to fit specific operational needs.

Conclusion

In conclusion, synchronous belt wheels are essential components that facilitate precise motion control in a wide range of mechanical systems. Their unique design and functionality offer significant advantages over traditional power transmission methods, making them invaluable in modern engineering applications. Whether in automotive engines or manufacturing lines, the impact of synchronous belt wheels is profound, underscoring their importance in enhancing efficiency and reliability across multiple sectors. As technology advances, the role of these components is likely to expand, further cementing their place in the future of mechanical design and engineering.