Telescopic Covers for Ball Screws Enhancing Durability and Performance in Machinery Applications

Understanding Telescopic Ball Screw Covers Design, Function, and Applications

In the realm of precision engineering and automated machinery, the importance of effective protection for mechanical components cannot be overstated. One such crucial component is the ball screw, which is widely employed in various applications ranging from CNC machinery to robotics. To ensure the longevity and reliable performance of ball screws, telescopic ball screw covers have emerged as an essential addition in many engineering designs.

What are Telescopic Ball Screw Covers?

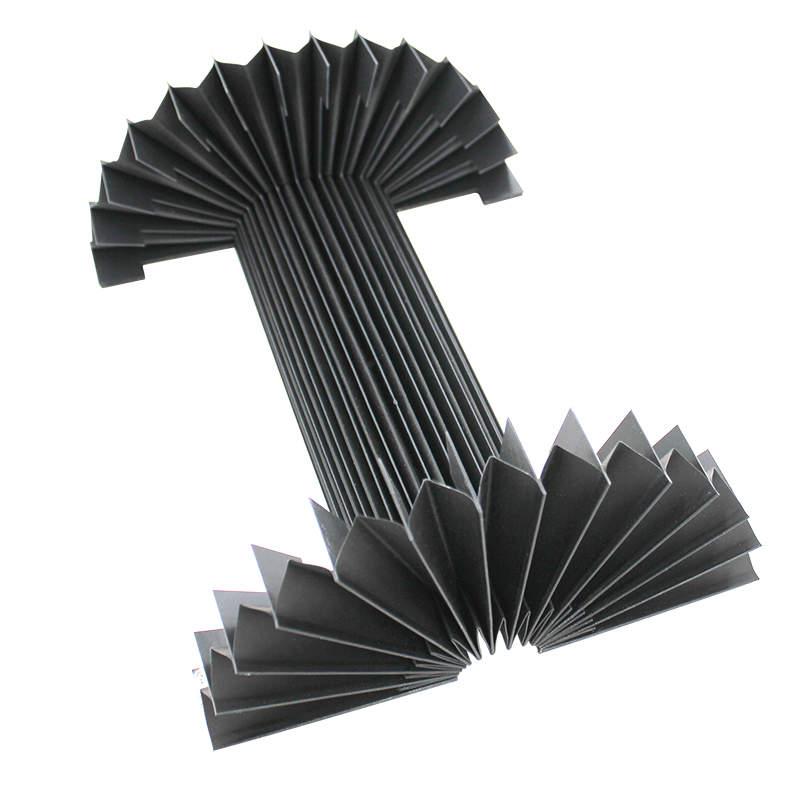

Telescopic ball screw covers are protective devices designed to shield the ball screw mechanism from environmental contaminants such as dust, dirt, debris, and moisture. They are typically constructed from materials like various plastics, stainless steel, or aluminum, which offer durability and resistance against wear and corrosion. The telescopic aspect refers to the expandable design that allows the cover to extend and retract as the ball screw moves, ensuring continuous protection throughout the operation.

Design Features

The design of telescopic ball screw covers is engineered to provide seamless functionality alongside maximum protection. Key features include

1. Multi-Stage Construction Most telescopic covers consist of several overlapping sections, which enable the cover to smoothly extend and retract without hindering the movement of the ball screw. This multi-stage design minimizes the risk of snagging while ensuring that no debris can penetrate the exposed areas.

2. Material Selection The choice of materials is pivotal in determining the cover's effectiveness. For instance, while plastic covers are lightweight and resistant to corrosion, metal covers, although heavier, provide better protection against impacts and extreme conditions.

3. Tailored Designs Depending on the specific application, telescopic covers can be customized to fit various sizes and shapes of ball screws. This adaptability ensures a snug fit that maximizes the protective capabilities.

4. Ease of Maintenance Many modern telescopic covers are designed for easy disassembly and cleaning, which is essential for maintaining the integrity of the ball screw over time.

telescopic ball screw covers

Functionality

The primary function of telescopic ball screw covers is to protect the ball screw assembly from foreign particles that can lead to wear and failure. By keeping contaminants at bay, these covers help maintain the smooth operation of the ball screw, thus prolonging its lifespan and reducing the frequency of maintenance.

Additionally, telescopic covers help minimize the risk of personal injury in environments where moving parts might pose dangers. By enclosing the ball screw, they offer a layer of safety for operators and maintenance personnel.

Applications

The applications for telescopic ball screw covers are vast and varied. They can be found in

- CNC Machines In environments where metal shavings and coolant fluids are present, telescopic covers are essential for safeguarding ball screws from harm. - Robotics In robotic applications, these covers provide protection against dust and other contaminants that can hinder robotic precision and performance.

- Material Handling Equipment Telescopic covers serve in various equipment like conveyors and lifts, where they protect moving parts from dirt that can impair function.

- Automotive and Aerospace Industries These covers are crucial in high-precision industries where even minute particulate contamination can lead to significant issues, ensuring consistent quality and reliability.

Conclusion

Telescopic ball screw covers play an indispensable role in the protection of vital mechanical components within various engineering applications. By extending the life of ball screws through effective contamination prevention, these covers are not just beneficial but essential for maintaining the efficiency and safety of machinery. As industries continue to push the boundaries of technology and automation, the importance of these protective solutions will only continue to grow, advocating for innovation in design and material use to enhance performance and durability. Overall, investing in quality telescopic ball screw covers is a strategic choice that underscores the significance of preventive maintenance in modern engineering practices.