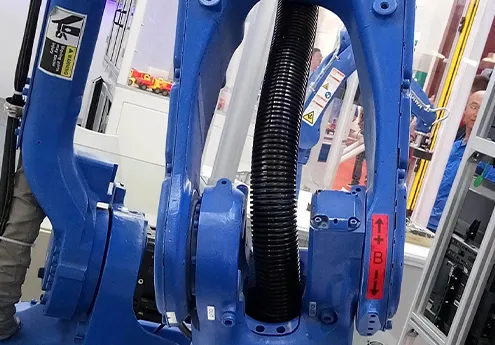

steel metal square telescopic accordion cylinder dust bellow cover

Telescopic bellows, essential components in contemporary machinery, play a crucial role in safeguarding moving parts from dust, debris, and other environmental hazards. Over the years, their innovative design and construction have positioned them as indispensable in various industrial and commercial applications. However, beyond their primary role, these devices embody a combination of engineering excellence and material science breakthroughs, making them a fascinating subject of study for both experts and enthusiasts alike.

From an engineering perspective, the continuous evolution of telescopic bellows exemplifies a commitment to innovation. Recent developments in computerized design techniques have allowed engineers to simulate various operating conditions, refining the bellows' performance long before they are manufactured. This foresight reduces the need for prototyping, which accelerates the development process and ensures that only the most efficient designs are brought to market. Implementing telescopic bellows necessitates a deep understanding of both the machinery they are coupled with and their operating environment. It requires expertise to tailor these components to meet specific requirements, taking into consideration factors like movement range, exposure conditions, and lifecycle expectations. It is this expertise, combined with empirical data and user feedback, which continues to propel the advancement of telescopic bellow technology. Moreover, trustworthiness in the manufacturing of telescopic bellows cannot be overstated. Industry standards and certifications ensure that these products meet stringent safety and performance criteria. Manufacturers who adhere to these standards are not merely selling a product but are providing assurance that their bellows will perform reliably under specified conditions, which in turn builds trust with consumers and industry professionals. In summary, telescopic bellows represent a confluence of expert engineering, advanced materials, and a commitment to safety and efficiency. They are more than just protective covers; they are a testament to the dedication of those in the field who continuously push the boundaries of what is possible in machinery protection. For businesses looking to invest in their future, selecting high-quality telescopic bellows is not just an option, but a mandate for sustained operational success.

From an engineering perspective, the continuous evolution of telescopic bellows exemplifies a commitment to innovation. Recent developments in computerized design techniques have allowed engineers to simulate various operating conditions, refining the bellows' performance long before they are manufactured. This foresight reduces the need for prototyping, which accelerates the development process and ensures that only the most efficient designs are brought to market. Implementing telescopic bellows necessitates a deep understanding of both the machinery they are coupled with and their operating environment. It requires expertise to tailor these components to meet specific requirements, taking into consideration factors like movement range, exposure conditions, and lifecycle expectations. It is this expertise, combined with empirical data and user feedback, which continues to propel the advancement of telescopic bellow technology. Moreover, trustworthiness in the manufacturing of telescopic bellows cannot be overstated. Industry standards and certifications ensure that these products meet stringent safety and performance criteria. Manufacturers who adhere to these standards are not merely selling a product but are providing assurance that their bellows will perform reliably under specified conditions, which in turn builds trust with consumers and industry professionals. In summary, telescopic bellows represent a confluence of expert engineering, advanced materials, and a commitment to safety and efficiency. They are more than just protective covers; they are a testament to the dedication of those in the field who continuously push the boundaries of what is possible in machinery protection. For businesses looking to invest in their future, selecting high-quality telescopic bellows is not just an option, but a mandate for sustained operational success.