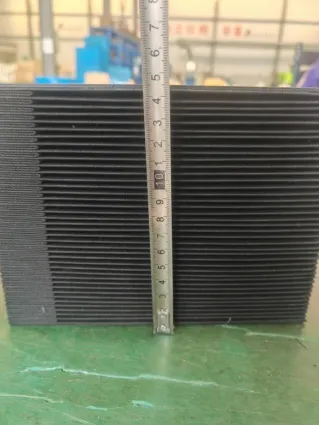

synchronous belt pulley

Toothed belt drives, commonly known as synchronous belt drives, are quintessential components in mechanical systems where precise motion control and power transmission are paramount. This innovative technology, characterized by its toothed structure, seamlessly integrates the benefits of both chain and flat belt drives. Delving into the toothed belt drive system unveils an intricate blend of engineering prowess and practical application, making it a preferred choice in various industrial sectors.

Authoritative studies and case studies have demonstrated the practical benefits of using toothed belt drives over other mechanical drive systems. For instance, research conducted within the automotive industry has highlighted the efficiency gains in fuel consumption and engine performance when using toothed belts for timing systems compared to traditional chain methods. These studies offer compelling evidence of the potential lifecycle cost savings and performance enhancements achievable through the adoption of toothed belt systems. When considering the implementation of toothed belt drives in your application, it is crucial to consult with industry experts who can guide the selection of materials and configuration for optimal performance. Expertise lies not only in the selection process but also in understanding the nuances of installation and maintenance. Proper tensioning, alignment, and the use of compatible pulleys are critical to maximizing the advantages offered by toothed belts. A high level of trustworthiness can be established through engagement with suppliers who have a proven track record in delivering high-quality toothed belt systems. Manufacturers who adhere to international standards and operate under stringent quality control processes ensure that the belts delivered meet the demanding specifications required for diverse applications. In conclusion, the utilization of toothed belt drives stands as a testament to modern engineering's ability to meet and exceed the challenges posed by various industrial sectors. They not only embody the fundamentals of precision and durability but also enhance operational efficiency and reduce environmental impacts through quieter and more reliable performance. As industries continue to march towards automation and precision, the reliance on toothed belt drives will undoubtedly remain a critical component of this industrial evolution.

Authoritative studies and case studies have demonstrated the practical benefits of using toothed belt drives over other mechanical drive systems. For instance, research conducted within the automotive industry has highlighted the efficiency gains in fuel consumption and engine performance when using toothed belts for timing systems compared to traditional chain methods. These studies offer compelling evidence of the potential lifecycle cost savings and performance enhancements achievable through the adoption of toothed belt systems. When considering the implementation of toothed belt drives in your application, it is crucial to consult with industry experts who can guide the selection of materials and configuration for optimal performance. Expertise lies not only in the selection process but also in understanding the nuances of installation and maintenance. Proper tensioning, alignment, and the use of compatible pulleys are critical to maximizing the advantages offered by toothed belts. A high level of trustworthiness can be established through engagement with suppliers who have a proven track record in delivering high-quality toothed belt systems. Manufacturers who adhere to international standards and operate under stringent quality control processes ensure that the belts delivered meet the demanding specifications required for diverse applications. In conclusion, the utilization of toothed belt drives stands as a testament to modern engineering's ability to meet and exceed the challenges posed by various industrial sectors. They not only embody the fundamentals of precision and durability but also enhance operational efficiency and reduce environmental impacts through quieter and more reliable performance. As industries continue to march towards automation and precision, the reliance on toothed belt drives will undoubtedly remain a critical component of this industrial evolution.