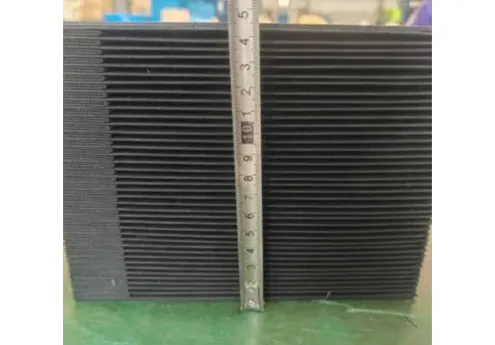

small cable track

Track cords, often an overlooked component in various technical and consumer applications, stand as silent sentinels ensuring safety, functionality, and reliability. Recognizing the transformative potential of track cords can elevate user experience, enhance product offerings, and build trust among consumers.

Additionally, the construction design of track cords is critical. Proper braiding techniques and tension settings are necessary to ensure they meet the rigorous standards required for specific applications. Expertise in this field involves an understanding of mechanical harmonics and the dynamic interactions between moving system components. This knowledge helps ensure optimal performance and durability of track cords, thereby extending equipment life and enhancing safety during use. Authoritativeness Industry Standards and Compliance As essential parts of many safety-critical applications, track cords must adhere to stringent industry standards and regulatory guidelines. Compliance with these standards is not only a matter of legal obligation but is also fundamental for maintaining consumer trust. Authorities like the ISO (International Organization for Standardization) often outline specifications for quality and performance that manufacturers must follow. For instance, in the automotive industry, any components that contribute to occupant safety, including seatbelt mechanisms powered by track cords, must comply with industry-specific standards. These standards ensure that every component performs reliably under varied and often rigorous conditions. Trustworthiness Building Consumer Confidence Trust plays a pivotal role in consumer choice and brand loyalty. By focusing on quality control, extensive testing, and transparent communication about compliance and performance metrics, manufacturers can build trust with their client base. Highlighting certifications and successful quality audits can also assure customers of a track cord's reliability and safety. Furthermore, testimonials and case studies regarding successful implementations of track cords across industries can demonstrate their efficacy and robustness. By showcasing detailed data and real-world performance metrics, companies not only underscore the reliability of their track cords but also affirm their commitment to quality and customer satisfaction. In conclusion, the unassuming track cord is a linchpin in the seamless function of devices and systems we often take for granted. Its role in enhancing safety, ensuring functionality, and promoting reliability cannot be overstated. By focusing on quality, rigorous testing, and adherence to industry standards, manufacturers can continue to assert the track cord’s indispensability while building a strong reputation for excellence and trustworthiness in their products.

Additionally, the construction design of track cords is critical. Proper braiding techniques and tension settings are necessary to ensure they meet the rigorous standards required for specific applications. Expertise in this field involves an understanding of mechanical harmonics and the dynamic interactions between moving system components. This knowledge helps ensure optimal performance and durability of track cords, thereby extending equipment life and enhancing safety during use. Authoritativeness Industry Standards and Compliance As essential parts of many safety-critical applications, track cords must adhere to stringent industry standards and regulatory guidelines. Compliance with these standards is not only a matter of legal obligation but is also fundamental for maintaining consumer trust. Authorities like the ISO (International Organization for Standardization) often outline specifications for quality and performance that manufacturers must follow. For instance, in the automotive industry, any components that contribute to occupant safety, including seatbelt mechanisms powered by track cords, must comply with industry-specific standards. These standards ensure that every component performs reliably under varied and often rigorous conditions. Trustworthiness Building Consumer Confidence Trust plays a pivotal role in consumer choice and brand loyalty. By focusing on quality control, extensive testing, and transparent communication about compliance and performance metrics, manufacturers can build trust with their client base. Highlighting certifications and successful quality audits can also assure customers of a track cord's reliability and safety. Furthermore, testimonials and case studies regarding successful implementations of track cords across industries can demonstrate their efficacy and robustness. By showcasing detailed data and real-world performance metrics, companies not only underscore the reliability of their track cords but also affirm their commitment to quality and customer satisfaction. In conclusion, the unassuming track cord is a linchpin in the seamless function of devices and systems we often take for granted. Its role in enhancing safety, ensuring functionality, and promoting reliability cannot be overstated. By focusing on quality, rigorous testing, and adherence to industry standards, manufacturers can continue to assert the track cord’s indispensability while building a strong reputation for excellence and trustworthiness in their products.