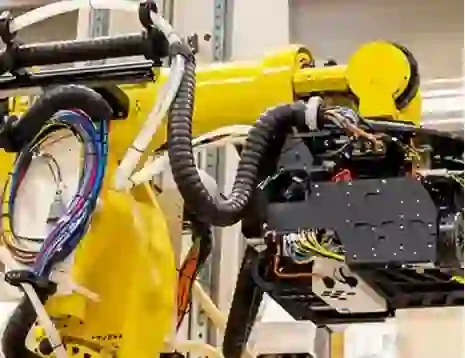

turbo systems chip conveyor

The Turbo Systems Chip Conveyor Revolutionizing Material Handling

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. One of the key innovations facilitating these demands is the Turbo Systems Chip Conveyor, a cutting-edge solution designed to streamline material handling processes in various industrial applications. This article explores the significance of chip conveyors, the unique features of the Turbo Systems design, and its impact on operational efficiency.

Understanding Chip Conveyors

Chip conveyors are mechanical devices used to transport metal chips, shavings, and other by-products produced during machining processes. Traditionally, these materials posed significant challenges; they could accumulate on workshop floors, create safety hazards, and detract from overall operational efficiency. The introduction of chip conveyors marked a pivotal moment in manufacturing, allowing for the automatic removal and management of these materials, thus enhancing productivity and workplace safety.

The Need for Advanced Solutions

As industries evolve, the demand for more efficient and versatile material handling solutions has surged. Companies are increasingly seeking equipment that not only reduces labor costs but also minimizes downtime associated with manual cleaning. The Turbo Systems Chip Conveyor meets these needs by providing robust and reliable performance, specifically engineered for various industrial environments.

Innovative Features of Turbo Systems Chip Conveyor

One of the most compelling aspects of the Turbo Systems Chip Conveyor is its unique design tailored to maximize efficiency

. Here are some of its standout features1. Versatile Design The Turbo Systems Chip Conveyor can handle a wide range of materials, including ferrous and non-ferrous metal chips, plastic scrap, and other by-products. This versatility makes it an invaluable asset in diverse sectors, such as automotive, aerospace, and general manufacturing.

turbo systems chip conveyor

2. Modular Configuration The system’s modular design allows for easy customization and integration with existing machinery. Manufacturers can configure the conveyor to suit specific operational requirements while ensuring seamless connectivity with CNC machines, lathes, and other equipment.

3. High Efficiency Turbo Systems has engineered its chip conveyor to operate with high throughput rates, effectively removing chips from the machining area without interruption. This continuous operation minimizes downtime and enhances overall productivity.

4. Durability and Maintenance Constructed from high-quality materials, the Turbo Systems Chip Conveyor is built to withstand the rigors of heavy industrial use. It requires minimal maintenance, a crucial benefit for manufacturers looking to reduce operational costs associated with downtime and repairs.

5. Enhanced Safety Features Safety is a paramount consideration in any industrial setting. The Turbo Systems design includes features that prevent spills and accidents associated with chip accumulation. Additionally, the conveyor setup can be configured to reduce noise levels, creating a safer and more pleasant working environment.

6. Environmentally Friendly By efficiently collecting and transporting metal chips and scrap, the Turbo Systems Chip Conveyor helps facilitate recycling efforts. This not only benefits the environment but also allows companies to reclaim materials and reduce waste disposal costs.

Impact on Operational Efficiency

The implementation of the Turbo Systems Chip Conveyor has a profound impact on operational efficiency. By automating the chip handling process, manufacturers can focus on core production tasks without the distractions and inefficiencies caused by manual clean-up efforts. This automation facilitates a continuous workflow, allowing for increased production rates and improved output quality. Moreover, it contributes to a cleaner, safer workplace, which can enhance employee morale and retention.

Conclusion

As industries continue to seek ways to maximize efficiency and streamline operations, the Turbo Systems Chip Conveyor stands out as a vital solution. Its versatile, durable, and efficient design not only addresses the challenges associated with chip management but also supports the broader goals of safety and sustainability within the manufacturing sector. Investing in such innovative technology is essential for businesses looking to maintain competitiveness in an ever-evolving marketplace. Thus, the Turbo Systems Chip Conveyor is not merely a piece of equipment; it is a transformative asset that can significantly enhance operational prowess and pave the way for future advancements in material handling.