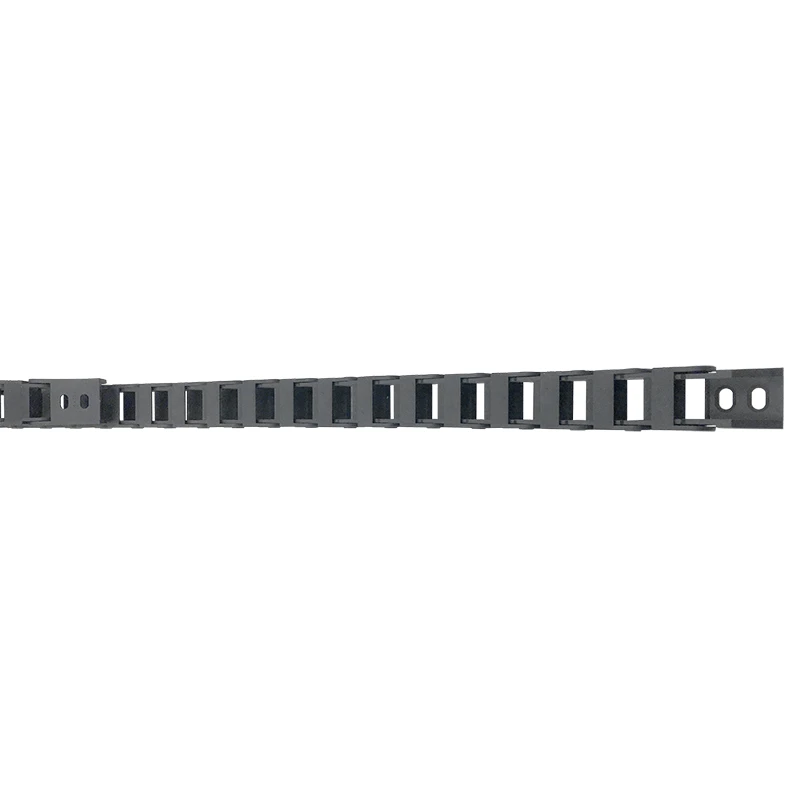

waterproof bellow cover

In industries where precision and durability are the cornerstones of operational success, equipment protection is not just an added feature—it's a necessity. Waterproof bellow covers represent a pivotal component in safeguarding machinery against the dual threats of mechanical wear and environmental exposure. To fully appreciate the significance of these covers, one must delve into their construction, application, and the unparalleled advantages they present.

Real-world experience with waterproof bellow covers highlights their transformative impact on maintenance schedules and operational reliability. Many industries have documented significant reductions in downtime following the installation of these covers. By effectively excluding moisture and particulates, machines require less frequent service interventions, resulting in lower maintenance costs and increased operational uptime. This reliability translates directly into a stronger bottom line and more predictable production cycles. Furthermore, the trustworthiness of waterproof bellow covers is reinforced by extensive testing and quality assurance processes. Manufacturers typically subject these covers to rigorous simulations that mimic the harshest operational environments they might encounter. Tests for tensile strength, elasticity, thermal resistance, and chemical stability ensure that each bellow cover not only meets but often exceeds expected performance metrics. This commitment to quality gives end-users confidence in their investment, knowing that they are shielded by robust and reliable equipment protection. In conclusion, waterproof bellow covers are more than a simple accessory; they are a strategic investment in machine longevity and operational efficiency. Their design, steeped in technical expertise and industry-specific knowledge, positions them as an authoritative solution in equipment preservation. As industries continue to evolve, embracing more complex machinery and confronting harsher environmental conditions, the role of waterproof bellow covers will undoubtedly grow, underscoring their essential place in the toolkit of any business focused on efficiency, reliability, and long-term success. Through real-world application and exhaustive testing, these covers stand as a testament to human ingenuity and the relentless pursuit of operational excellence.

Real-world experience with waterproof bellow covers highlights their transformative impact on maintenance schedules and operational reliability. Many industries have documented significant reductions in downtime following the installation of these covers. By effectively excluding moisture and particulates, machines require less frequent service interventions, resulting in lower maintenance costs and increased operational uptime. This reliability translates directly into a stronger bottom line and more predictable production cycles. Furthermore, the trustworthiness of waterproof bellow covers is reinforced by extensive testing and quality assurance processes. Manufacturers typically subject these covers to rigorous simulations that mimic the harshest operational environments they might encounter. Tests for tensile strength, elasticity, thermal resistance, and chemical stability ensure that each bellow cover not only meets but often exceeds expected performance metrics. This commitment to quality gives end-users confidence in their investment, knowing that they are shielded by robust and reliable equipment protection. In conclusion, waterproof bellow covers are more than a simple accessory; they are a strategic investment in machine longevity and operational efficiency. Their design, steeped in technical expertise and industry-specific knowledge, positions them as an authoritative solution in equipment preservation. As industries continue to evolve, embracing more complex machinery and confronting harsher environmental conditions, the role of waterproof bellow covers will undoubtedly grow, underscoring their essential place in the toolkit of any business focused on efficiency, reliability, and long-term success. Through real-world application and exhaustive testing, these covers stand as a testament to human ingenuity and the relentless pursuit of operational excellence.