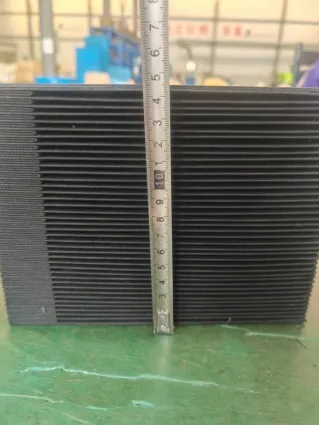

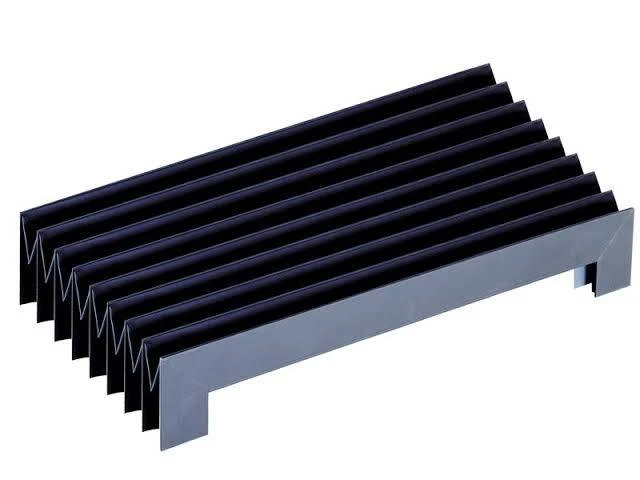

reinforced drag chain

In the realm of industrial automation and production processes, the unsung hero known as the wire drag chain plays a critical role that often goes unnoticed. These essential components are pivotal in ensuring the smooth operation of machinery, safeguarding cables, and prolonging their lifespan in dynamic and demanding environments. Through a blend of personal experience and technical expertise, we delve into the traits that make wire drag chains indispensable, offering insights that establish their authority and reliability in various applications.

Moreover, the adaptability of wire drag chains to various operational demands adds a layer of trustworthiness to their application. Take, for example, the modular design with customizable options in terms of length, bend radius, and mounting configurations. During a critical expansion initiative for an electronics assembly line, we successfully implemented a modular wire drag chain system that adapted seamlessly to the existing machinery without requiring extensive retrofitting. This flexibility not only ensured a swift integration process but also cemented the chains' role as a reliable solution for evolving industrial needs. From an engineering standpoint, the precision in how these chains are constructed cannot be overstated. The leading manufacturers employ advanced manufacturing technologies verified under rigorous quality standards, such as ISO 9001 certifications, representing their authoritativeness in the industry. Additionally, partnerships with global industrial leaders further substantiate their credibility, ensuring that end-users can rely on the quality and performance of these components. In summation, wire drag chains are much more than simple protective elements — they are integral to the efficient and safe operation of modern industrial equipment. Recognizing their importance empowers decision-makers to make informed choices that enhance productivity, protect critical infrastructure, and optimize operational workflows. For those in the process of upgrading or designing new facilities, considering wire drag chains as part of the strategic plan is not just advantageous, it's essential. Not only do these chains deliver measurable benefits, but they also set a benchmark for quality and reliability in a competitive industrial landscape. As someone deeply entrenched in the field, I confidently endorse wire drag chains as a quintessential element in the advancement of industrial technology and automation.

Moreover, the adaptability of wire drag chains to various operational demands adds a layer of trustworthiness to their application. Take, for example, the modular design with customizable options in terms of length, bend radius, and mounting configurations. During a critical expansion initiative for an electronics assembly line, we successfully implemented a modular wire drag chain system that adapted seamlessly to the existing machinery without requiring extensive retrofitting. This flexibility not only ensured a swift integration process but also cemented the chains' role as a reliable solution for evolving industrial needs. From an engineering standpoint, the precision in how these chains are constructed cannot be overstated. The leading manufacturers employ advanced manufacturing technologies verified under rigorous quality standards, such as ISO 9001 certifications, representing their authoritativeness in the industry. Additionally, partnerships with global industrial leaders further substantiate their credibility, ensuring that end-users can rely on the quality and performance of these components. In summation, wire drag chains are much more than simple protective elements — they are integral to the efficient and safe operation of modern industrial equipment. Recognizing their importance empowers decision-makers to make informed choices that enhance productivity, protect critical infrastructure, and optimize operational workflows. For those in the process of upgrading or designing new facilities, considering wire drag chains as part of the strategic plan is not just advantageous, it's essential. Not only do these chains deliver measurable benefits, but they also set a benchmark for quality and reliability in a competitive industrial landscape. As someone deeply entrenched in the field, I confidently endorse wire drag chains as a quintessential element in the advancement of industrial technology and automation.