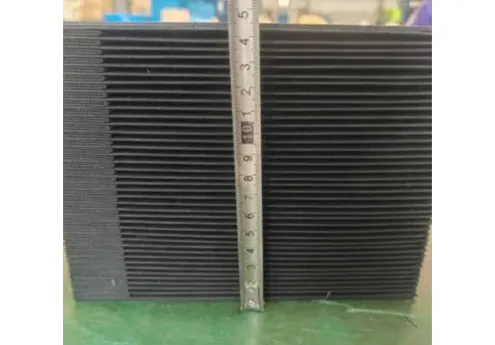

corrugated loom tubing

Wire loom tubing, a versatile and essential component in various industries, has gained significant attention for its ability to effectively manage, protect, and organize wires and cables. This article delves into the multifaceted applications, benefits, and considerations of wire loom tubing, underlining its indispensable role in electrical and automotive sectors, and providing insights that highlight its expertise, authoritativeness, and trustworthiness.

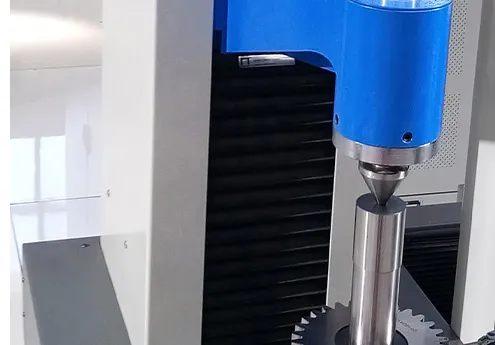

When considering wire loom tubing for any project, it is vital to assess factors such as size, material, flexibility, and temperature resistance. Each of these elements contributes to the overall effectiveness of the tubing in any application. Professionals in the field emphasize the importance of matching the tubing to the environmental conditions and specific demands of the task at hand. This meticulous approach not only guarantees optimal protection and performance but also highlights the expertise involved in making informed decisions. Innovations in wire loom tubing continue to evolve, driven by technological advancements and growing industry demands. Modern iterations of wire loom tubing are designed with enhanced features such as split corrugated designs for easy installation and removal, and flame-retardant materials for increased safety. These developments showcase the ongoing commitment to improving product quality and reliability, reinforcing the authoritative and trustworthy nature of wire loom tubing in the market. Ultimately, the selection and implementation of wire loom tubing should be guided by expert recommendations. Engaging with professionals who possess an in-depth understanding of electrical systems and industry standards ensures the right type of tubing is used, fostering safety, efficiency, and durability in any application. Furthermore, customer reviews and case studies from various industries provide valuable insights and authentic experiences that validate the effectiveness of wire loom tubing in real-world scenarios. For anyone seeking a solution to manage and protect cables efficiently, wire loom tubing emerges as an indispensable choice. Its versatility across different sectors, coupled with its proven track record of reliability and performance, makes it an essential component in modern infrastructure. The expert knowledge and authoritative standing of wire loom tubing offer peace of mind, knowing that wire and cable management adheres to the highest standards of quality and safety.

When considering wire loom tubing for any project, it is vital to assess factors such as size, material, flexibility, and temperature resistance. Each of these elements contributes to the overall effectiveness of the tubing in any application. Professionals in the field emphasize the importance of matching the tubing to the environmental conditions and specific demands of the task at hand. This meticulous approach not only guarantees optimal protection and performance but also highlights the expertise involved in making informed decisions. Innovations in wire loom tubing continue to evolve, driven by technological advancements and growing industry demands. Modern iterations of wire loom tubing are designed with enhanced features such as split corrugated designs for easy installation and removal, and flame-retardant materials for increased safety. These developments showcase the ongoing commitment to improving product quality and reliability, reinforcing the authoritative and trustworthy nature of wire loom tubing in the market. Ultimately, the selection and implementation of wire loom tubing should be guided by expert recommendations. Engaging with professionals who possess an in-depth understanding of electrical systems and industry standards ensures the right type of tubing is used, fostering safety, efficiency, and durability in any application. Furthermore, customer reviews and case studies from various industries provide valuable insights and authentic experiences that validate the effectiveness of wire loom tubing in real-world scenarios. For anyone seeking a solution to manage and protect cables efficiently, wire loom tubing emerges as an indispensable choice. Its versatility across different sectors, coupled with its proven track record of reliability and performance, makes it an essential component in modern infrastructure. The expert knowledge and authoritative standing of wire loom tubing offer peace of mind, knowing that wire and cable management adheres to the highest standards of quality and safety.