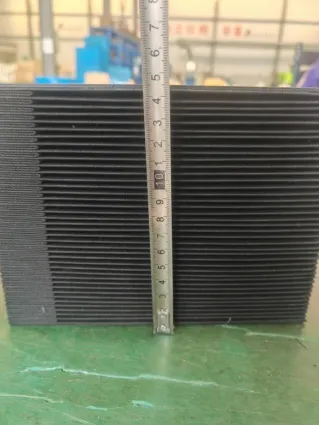

corrugated wire loom

In the world of automotive and electronic wiring, organization and protection of cables are paramount. Yellow split wire loom has emerged as a popular solution for both professionals and DIY enthusiasts aiming to enhance the longevity and safety of their wiring projects. This unique product not only safeguards wires from abrasion, moisture, and environmental chemicals but also aids in the seamless identification of different wire groups in complex systems.

Beyond the realm of automotive applications, yellow split wire loom is extensively employed in maritime, aerospace, and industrial settings. Its material composition, typically comprising polyethylene or polypropylene, offers a high melting point and resistance to a wide range of chemicals and solvents found in these industries. As a result, cables housed within the loom benefit from prolonged durability and the infrastructure remains code-compliant and secure over time. From an expert perspective, the efficacy of yellow split wire loom is not only rooted in its durable material properties but also in its adaptability to evolving industry standards and environmental regulations. In today's eco-conscious market, ensuring that materials are recyclable and leave minimal environmental impact is crucial. Wire loom products, particularly those made from eco-friendly materials, cater to this requirement, providing a sustainable option for companies looking to minimize their carbon footprint. Furthermore, trustworthiness in the quality of yellow split wire loom is supported by numerous certifications and compliance standards that these products meet. Many manufacturers adhere to guidelines such as RoHS (Restriction of Hazardous Substances) and UL (Underwriters Laboratories), providing assurance to users that the looms they are incorporating into their systems are safe and reliable. In conclusion, the adoption of yellow split wire loom presents an array of benefits that cater to safety, efficiency, and environmental considerations. Its ability to shield and organize wires while simplifying identification processes makes it a valuable asset in any wiring project. Whether one is an industry veteran or a novice DIY enthusiast, the integration of this product can significantly enhance the operational integrity and aesthetic organization of wiring systems, solidifying its status as an essential tool in modern electrical engineering.

Beyond the realm of automotive applications, yellow split wire loom is extensively employed in maritime, aerospace, and industrial settings. Its material composition, typically comprising polyethylene or polypropylene, offers a high melting point and resistance to a wide range of chemicals and solvents found in these industries. As a result, cables housed within the loom benefit from prolonged durability and the infrastructure remains code-compliant and secure over time. From an expert perspective, the efficacy of yellow split wire loom is not only rooted in its durable material properties but also in its adaptability to evolving industry standards and environmental regulations. In today's eco-conscious market, ensuring that materials are recyclable and leave minimal environmental impact is crucial. Wire loom products, particularly those made from eco-friendly materials, cater to this requirement, providing a sustainable option for companies looking to minimize their carbon footprint. Furthermore, trustworthiness in the quality of yellow split wire loom is supported by numerous certifications and compliance standards that these products meet. Many manufacturers adhere to guidelines such as RoHS (Restriction of Hazardous Substances) and UL (Underwriters Laboratories), providing assurance to users that the looms they are incorporating into their systems are safe and reliable. In conclusion, the adoption of yellow split wire loom presents an array of benefits that cater to safety, efficiency, and environmental considerations. Its ability to shield and organize wires while simplifying identification processes makes it a valuable asset in any wiring project. Whether one is an industry veteran or a novice DIY enthusiast, the integration of this product can significantly enhance the operational integrity and aesthetic organization of wiring systems, solidifying its status as an essential tool in modern electrical engineering.